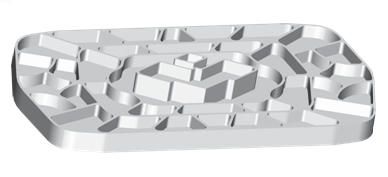

Setsi sa ho qetela sa carbide CNC

Tlhaloso e Khutšoanyane:

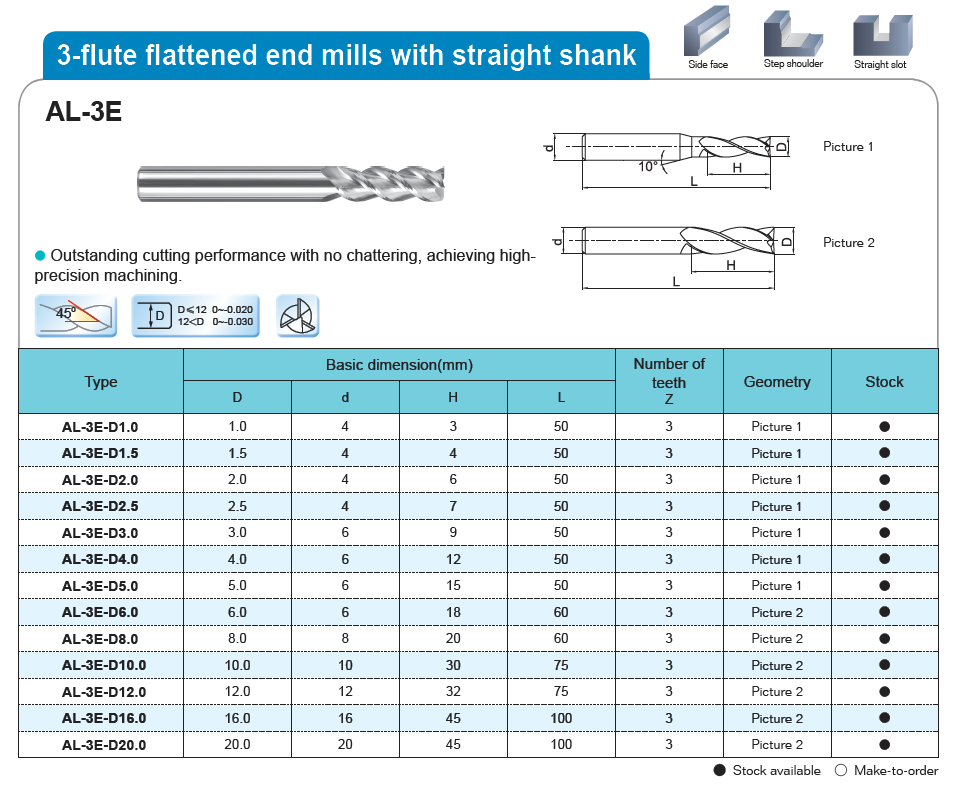

AL series 3-flute flattened end mill with straight shank end mill e loketse haholo machining ea AL.

Re na le boiphihlelo bo pharaletseng mosebetsing ona mme re ka u fa hoo e batlang e le mefuta ea limilili tse tiileng tsa carbide.

AL letoto Selelekela

AL series end mills for AL machining.AL series end Mills ke lisebelisoa tse phahameng tsa ho itšeha tse etselitsoeng lits'ebetso tsa ho sila. Li etselitsoe ho tlosa thepa ka nepo ho li-workpieces le ho fana ka sephetho se setle sa bokaholimo le ho nepahala ha boholo. Li-mill tsa ho qetela tsa AL li entsoe ka thepa ea boleng bo holimo joalo ka carbide e tiileng kapa tšepe ea lebelo le phahameng bakeng sa ho tšoarella le bophelo bo bolelele. Lisebelisoa tsena tsa ho qetela li na le likarolo tse nepahetseng tsa ho itšeha 'me li tla ka mefuta e fapaneng ea li-geometri tse kang lisekoere, nko ea bolo, radius ea sekhutlo le li-profiles tse thata. Moralo oa lekolilo oa li-mill tsa ho qetela tsa letoto la AL o ntlafalitsoe ho fana ka phallo e sebetsang ea li-chip, ho thibela chip buildup le ho fokotsa tlhahiso ea mocheso nakong ea mochini. Sena se thusa ho lelefatsa bophelo ba lisebelisoa le ho boloka ts'ebetso e tsitsitseng ea ho itšeha. Litlhophiso tsa lekolilo li ka fapana, ho kenyeletsoa meralo ea lekolilo tse peli, tse tharo kapa tse nne, ho latela litlhoko tse ikhethang tsa mochini. Li-mill tsa ho qetela tsa letoto la AL li fumaneha ka boholo bo fapaneng, bophara le bolelele ho lumellana le mesebetsi e fapaneng ea machining le lisebelisoa tsa mosebetsi. Li sebelisoa hangata liindastering tse fapaneng ho kenyeletsoa sefofane, likoloi, ho etsa hlobo, le lisebelisoa tse akaretsang tsa machining. Ka kakaretso, li-mill tsa ho qetela tsa letoto la AL ke lisebelisoa tse ka tšeptjoang le tse tenyetsehang tse fanang ka ts'ebetso e phahameng ea ho itšeha, ho nepahala le ho tšoarella bakeng sa ts'ebetso e fapaneng ea ho sila.

Boleng bo holimo ba lisebelisoa le ho tlosoa ha li-chips tse ntle ho ntlafatsa maemo a ho itšeha le ho lelefatsa bophelo ba lisebelisoa haholo.

Chip pocket e nang le sebopeho se ikhethileng e fana ka ts'ebetso e ntle haholo esita le ho machining a slot le cavity.

Mohaho o bohale le moralo o moholo oa helical angle ka katleho o thibela bohale bo hahiloeng.

Moralo oa anti-vibration oa moeli o felletseng o ka hatella moqoqo nakong ea machining le ho ntlafatsa boleng ba bokaholimo.

Mofuta oa sesebelisoa: AL-3E-D6.0 Litekanyo: Ø6.0mm

Lisebelisoa tsa mosebetsi: LC4

Lebelo le potolohang: 13000r/min (250m/min)

Lebelo la ho fepa: 1950mm/min (0.15mm/r)

Axial seha botebo: ap=9.0mm

Botebo ba ho itšeha ka mahlaseli: ae = 1.0mm

Mokhoa oa ho itšeha:Machining a rarahaneng a cavity

Sistimi ea ho futhumatsa: ho foka moea

Sesebelisoa sa mochini: MIKRON UCP 1000

Paramethara

Kopo

LBH

Ho ea ka sebōpeho seo re nang le mefuta e mengata haholo , tse kang flattened end mill, radius end mill, ball nose end mill, high-feed-rate end mill, long neck end mill, leloala le lenyenyane la hlooho joalo-joalo.

Ntho e ka sehloohong e fapaneng ke litlhoko tsa ho sebetsa: li-end Mills ke tsa ho sila, athe likotoana tsa ho cheka ke tsa ho cheka le ho tsosolosa. Le hoja maemong a mang, mochini o silang le oona o khona ho phunya, empa ha se oona o ka sehloohong.

Haeba mofuta oo re nang le ona setokong, bongata bofe kapa bofe bo tla loka.

Ee, re ka u etsetsa tlhophiso joalo ka litlhoko tsa hau.

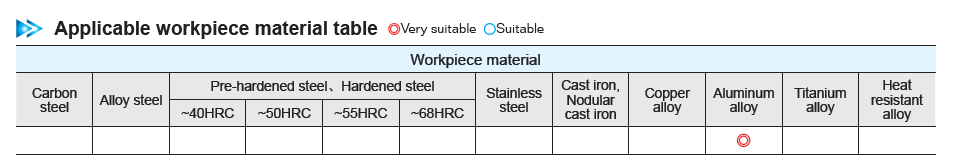

Ntlha ea pele, thepa ea workpiece.

Ea bobeli, sebopeho le lintlha tsa boholo: bophara ba shank, bophara ba lekolilo, bolelele ba lekolilo le bolelele bohle, palo ea meno.

Ea boraro, haeba u hloka ho itlhophisa, re fe setšoantšo se tla ba betere.