Solid Carbide Drills General Machining Boring Tool

Tlhaloso e Khutšoanyane:

GD series General-purpose twist drill drill versatile, for machining high performance machining in mefuta e fapaneng ea lintho tse bonahalang mohlala P(tšepe), M(Stainless steel), K(cast iron).Re na le boiphihlelo bo pharaletseng ba ts'ebetso lefapheng lena mme re ka u fa tse ngata mefuta eo u e hlokang. Khamphani ea rona e ka boela ea etsa li-drill tsa tungsten carbide (li-drill bits, carbide burr joalo-joalo) joalo ka litlhoko tsa hau.

Sehlahisoa Selelekela

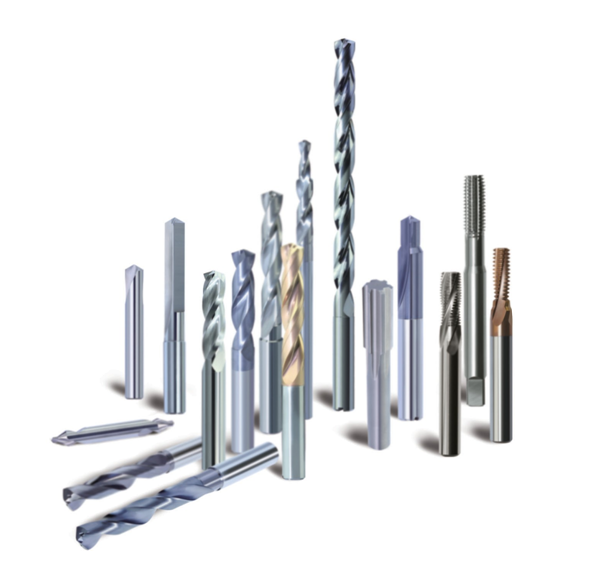

Lisebelisoa tse khathollang ka pono

| Diboro | Lisebelisoa tse tiileng tsa carbide |

| Li-drill tse sa tebang tsa indexable | |

| Reamers | Li-reamers tse tiileng tsa carbide |

| Li-cutters tsa khoele | Li-cutters tse tiileng tsa carbide |

| Litsila tse tiileng tsa carbide |

Kakaretso ea lisebelisoa tsa ho cheka

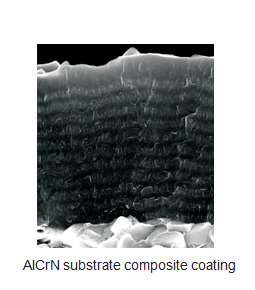

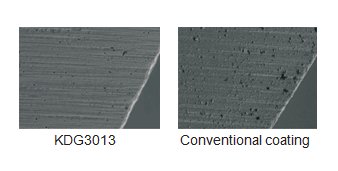

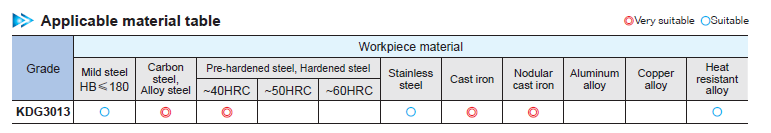

Sehlopha se koahetsoeng:KDG3013Motsoako o mocha oa motsoako oa AlCrN, o nang le khanyetso e ntle ea abrasion le khanyetso ea tlamo, e ntlafatsa botsitso ba moeli o kentsoeng. Theknoloji e ikhethang ea ho roala ka mor'a phekolo e fokotsa ka mokhoa o atlehang khanyetso ea ho itšeha bakeng sa ho tlosoa ha chip le tšireletso e phahameng.

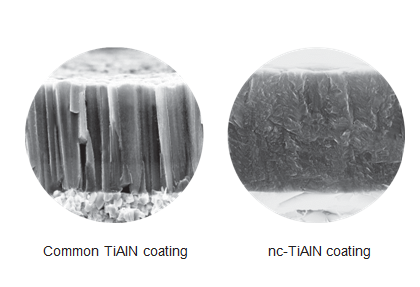

KDG303:Ultra-fine carbide substrate e nang le matla a phahameng, ho tiea le ho se mamelle, hammoho le coating ea nano-structured nc-TiAlN e reretsoeng ho ntlafatsa ts'ebetso ea ho cheka, e etsa bonnete ba hore lisebelisoa li na le boima bo phahameng haholo le boima. Theknoloji e ikhethang ea ho roala e fana ka lisebelisoa tse boreleli le ho hanyetsa ka mokhoa o babatsehang oa ho apara, 'me botsitso bo ikhethang ba mocheso le botsitso ba lik'hemik'hale li fana ka tšireletso e sebetsang bakeng sa ho itšeha.

Likaroloana

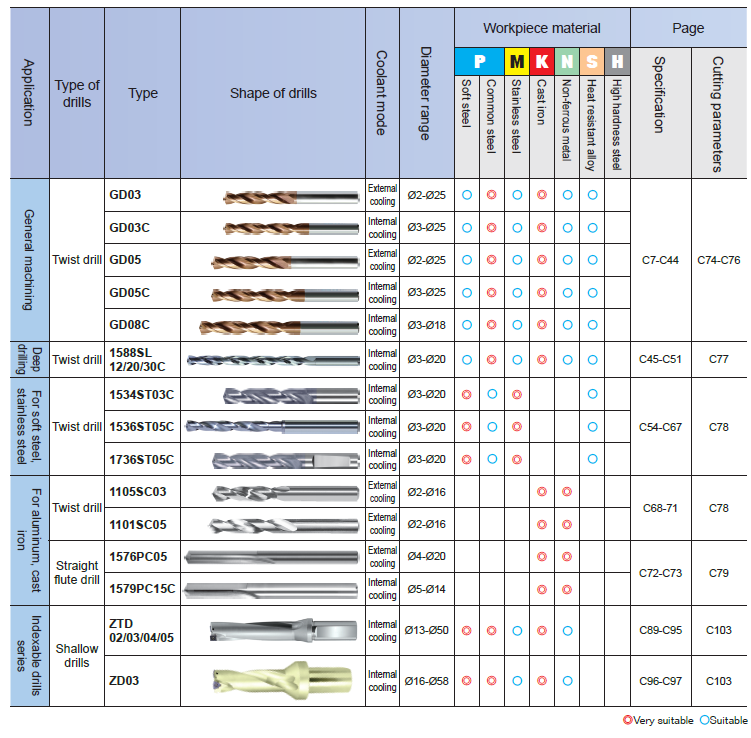

Letoto la GD le na le mefuta e mengata ea lits'ebetso. Ho na le likarolo tse kang tse latelang:

1. Mefuta e mengata, bakeng sa ho sebetsa ka mokhoa o phahameng ka mokhoa o phahameng oa lisebelisoa tse fapaneng mohlala P (tšepe), M (tšepe e sa hloekang), K (Cast iron).

2. Linear itšeha bohale le matla a phahameng. Mohaho o ntlafalitsoeng oa sebaka sa ho cheka bakeng sa ts'ebetso e ntle ea ho itšeha.

3. Ketsiso hammoho le teko bakeng sa tshebetso e phahameng ka kakaretso.

4. Setsebi ka mor'a ho phekoloa bakeng sa ho roala ho tiisa hore ho na le khanyetso e phahameng ea machining.

5. Moralo oa moeli o habeli bakeng sa botsitso bo ntlafalitsoeng ba mochini.

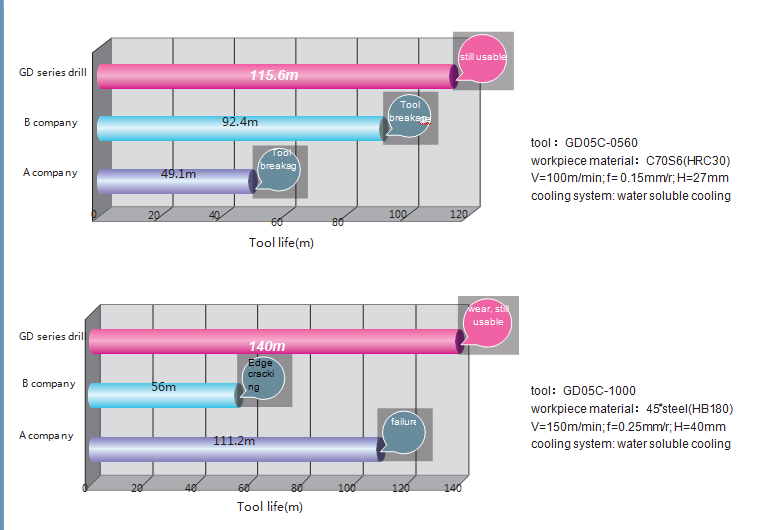

Papiso ea teko ea li-insert abrasion

Bophelo ba lisebelisoa tse telele le bo tsitsitseng

E ikhethang ka ho nepahala ha mochini

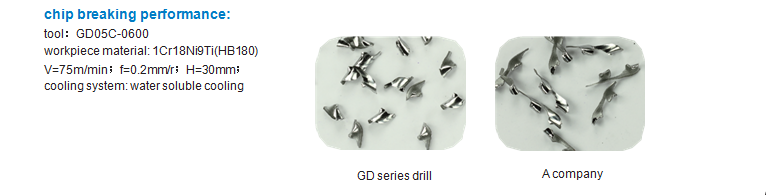

Ts'ebetso e ntle ea ho senya chip

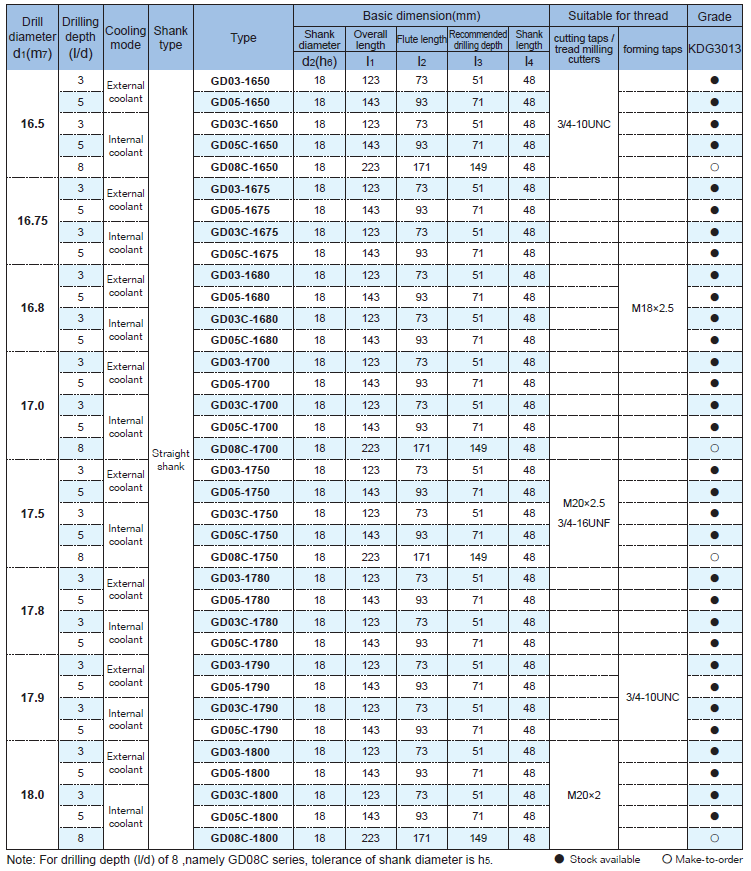

Paramethara

Kopo

LBH

Ntho e ka sehloohong e fapaneng ke litlhoko tsa ho sebetsa: li-end Mills ke tsa ho sila, athe likotoana tsa ho cheka ke tsa ho cheka le ho tsosolosa. Le hoja maemong a mang, mochini o silang le oona o khona ho phunya, empa ha se oona o ka sehloohong.

Haeba mofuta oo re nang le ona setokong, bongata bofe kapa bofe bo tla loka.

Ee, re ka u etsetsa tlhophiso joalo ka litlhoko tsa hau.

Ntlha ea pele, thepa ea workpiece.

Ea bobeli, lintlha tsa boholo: bophara ba ho cheka, mofuta oa shank, botebo ba ho phunya, bolelele ba lekolilo le bolelele bohle, mokhoa oa ho pholisa.

Ea boraro, haeba u hloka ho itlhophisa, re fe setšoantšo se tla ba betere.